INTELLIGENT RECOVERY PROTECTS OUR HABITAT

Our processing centre and our collaboration with innovative partner companies enable us to offer our customers a full recovery package.

RECOVERY TECHNIQUES

Bulk backfill

For waste (e.g. filter cake, furnace linings, foundry sand, bottom ash, filter dust, sold waste from the treatment of exhaust gases, etc.), provided that they meet the following requirements:

- Rough scrap metal separation

- Residual moisture of 10-15 %

- Residual organic matter of < 5 %

- Grain size up to approx. 60 mm

- Geomechanical compressive strength

- Safe to handle in terms of occupational safety

Big bag backfill

Waste that does not meet the criteria for bulk waste are put into a recoverable form by the treatment in a processing plant and packed into big bags in our conditioning plant.

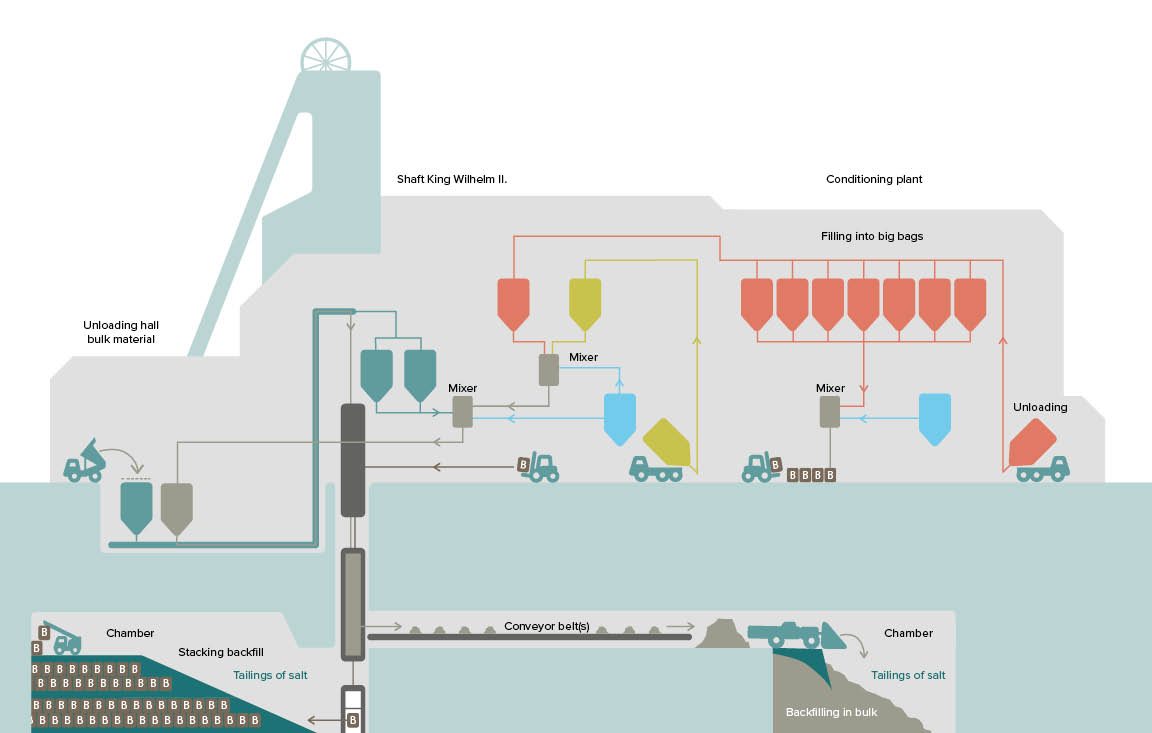

CONDITIONING PLANT

The conditioning plant is available to treat and then package waste for disposal in the mines in Heilbronn and Bad Friedrichshall. Particulate, liquid and filter cake waste are processed here and packed into big bags. Bulk waste is unloaded in a hall and processed into mine grout.

PROCESSING CENTRE

In an area of 10,000 m² in Bad Friedrichshall, there are processing and treatment plants for treating particulate or bulky waste from all sources, e.g. filter dust, slag, construction waste, soils or foundry sands, and making them into construction materials. This is preceded by an efficient recovery of ferrous and non-ferrous metals takes place in a multi-stage process. The metals are recycled.

QUALITY ASSURANCE

We attach great value to a constant improvement of the production and business processes that we manage via our quality management system.

We are certified in accordance with:

– ISO 9001:2015 (quality)

– ISO 14001:2015 (environment)

– ISO 50001 (energy)

– German Ordinance on Specialised Waste Management Companies (EfBV)